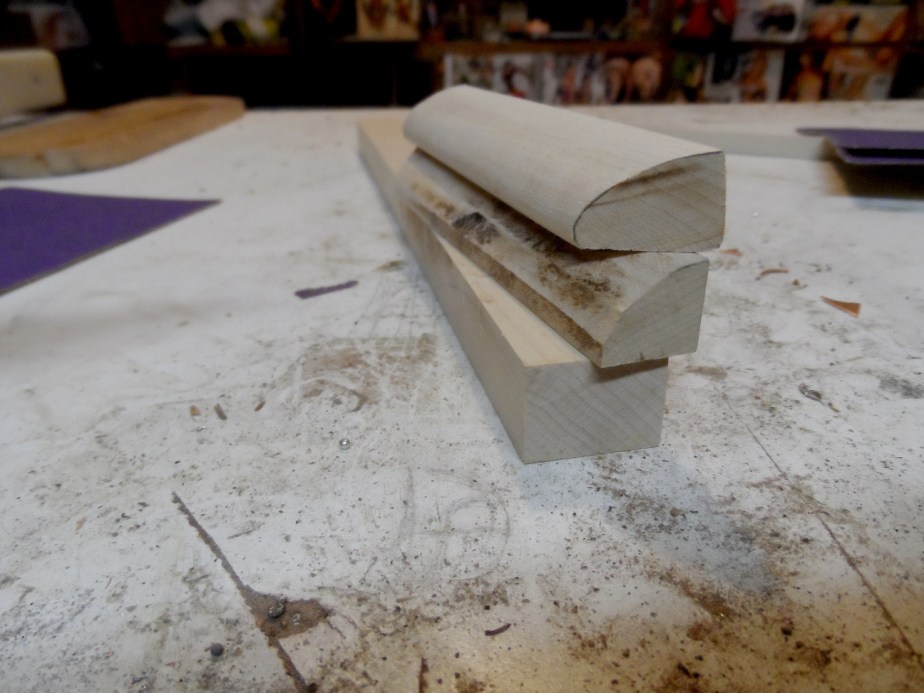

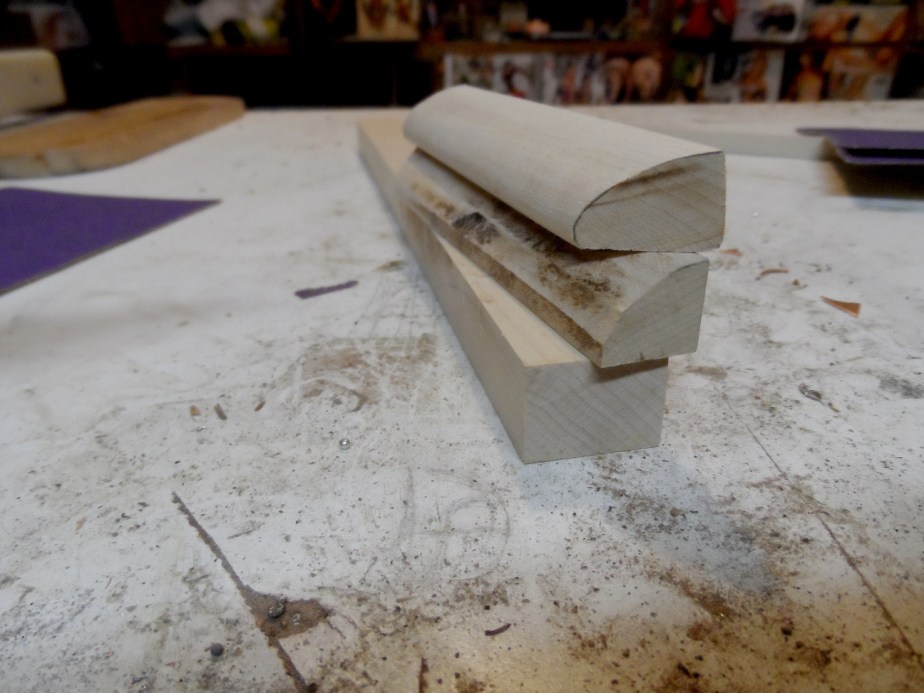

For Day 7 I’m using a furniture repair I just got done with for a customer. Its an Ethan Allen table.

Not so much creativity going on in this piece, more duplicating to match. Its not my favorite kinda shop time although every repair done I learn a new trick or two. (Side note: this table originally came to my shop eight months ago for a repair. Click here to see those repairs.)

The table owner’s dog ate one corner off.

Now the table was back due to the same dog chewing a different corner up.

The trick I learned on this project was because of the problem with the natural ambering (turning orangeish) that happens over time.

Trying to instantly amber a fresh piece to match took some creative problem solving.

To amber wood is to condition the wood after assembly before staining with red and yellow food coloring. Instantly the wood turns orange.

Next apply the stain that best matches the pieces in question. Once the stain is applied the shocking orange is gone and the perfect amber shows up with the stain color blended in on top to match.

On these kinds of repairs, the staining and finishing is often harder than the woodwork aspect.

And that’s Tony’s tips!